VOCs on the Paint Label, a guide for San Francisco Architects

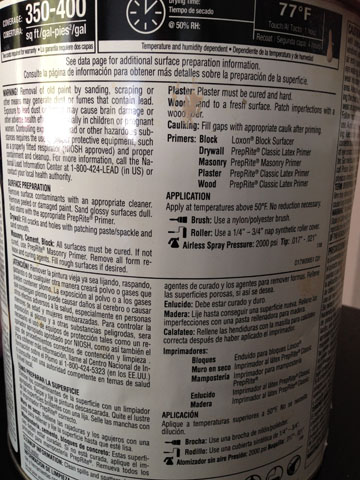

We encourage folks to judiciously read labels on products just like most seek nutrition content on food labels. Most people are tricked by the marketing claims from product suppliers and their representatives. We as practicing San Francisco Architects have done hundreds of presentations on the topic of Indoor Air Quality up and down the west coast and have been quite surprised to see how many people take a product’s claims at face value.

Most categories of so called “better” paints can be categorized into Low or Zero-VOC and such paint products are routinely specified in projects seeking LEED certification or any other “green” label.

It is extremely important to understand that there is no such thing as a Zero-VOC paint. All paints have Glycols, Petrochemicals and/or their derivatives, added colorants, biocides and fungicides and many other chemicals to give them commonly sought characteristics, such as durability, scratch resistance etc. Besides this, most paints comply with Federal and State regulations for VOCs.

The regulations that impose limits on VOC content (not emissions) in Architectural Coatings are EPA’s national regulations and here in California, San Francisco Architects have Bay Area Air Quality Management District‘s Rule 8 or the more stringent South Coast Air Quality Management District’s Rule 1113. It is important to note that these regulations are limiting VOC content and not emissions. VOC Content is what ever is sold in a container at the point of sale. Once a paint product is applied there could be thousands of micrograms of emissions (often referred to as Off-gassing) per square meter of the material per hour but those aren’t regulated let alone limited.

If manufacturers are following national regulation (EPA ) for limiting VOC content, they are in compliance with as high as 250 grams of VOCs per litre for flat interior coatings and as high as 380 gram/litre for non-flat coatings. BAAQMD’s Rule 8 has limits as high as 100 grams of VOCs per litre for flat coatings and 150 grams/litre for non-flat coatings. SCAQMD’s Rule 1113, which is the most stringent in the country has limits established at 50 grams of VOCs per litre for both flat and non-flat coatings

Based on these limits paint manufacturing companies are in compliance for VOC content as high as 249 grams/litre at the national level or even in the most stringent districts, for as high as 49 grams per litre of the paint container. These same companies end up marketing their products as low or Zero-Voc or even non-toxic. Some very popular paint products are advertised as “non-toxic” and yet the labels or MSDS sheets don’t account for colorants or other additives or emissions. These same products only guarantee the “products’ stability” under “normal” conditions, have strict first-aid directions and further ask for “protective equipment” during application and “sufficient ventilation”.

A very important thing to note is that colorant, additives (for microbial properties or to make a paint more workable etc.) aren’t included in these limits and there are a significant number of “exempt” compounds/VOCs which aren’t accounted for either.

There is significant work that is needed to improve testing methods that are used to measure VOC content and also toward establishing stricter regulations that include colorants, additives and account for “Exempt” compounds. There also needs to be considerable attention given to “VOC Emissions” which are a result of conditions that aren’t “normal”and more commonly a result of the inherent nature of VOCs.

In short a manufacturer’s self-declaration should not prevent folks to probe further, it might even be better to look at third party certifications, such as Green seal or Indoor Advantage Gold, but do note that even these certification systems use the current regulations as a matrix.